Crealet presents its innovative warp tension solutions at Techtextil 2024

Crealet is the world leader in sophisticated warp feeding technology and tailored solutions. Controlled warp tension stands also for controlled fabric quality. The Swiss firm presents its latest developments for technical textile applications at Techtextil 2024 in Frankfurt, Germany.

The year 2023 was notably successful for Crealet, with a significant increase in sales compared to the previous year. This increase is the result of growing customer demand for optimisation and automation of the warp feeding process, also taking sustainability aspects into account. This trend reflects a major shift towards intelligent warp feeding technology also possible by converting an existing manual into an automated system. Such investments enable mills to significantly improve quality, efficiency and productivity.

KAST ECR for ribbon weaving mills

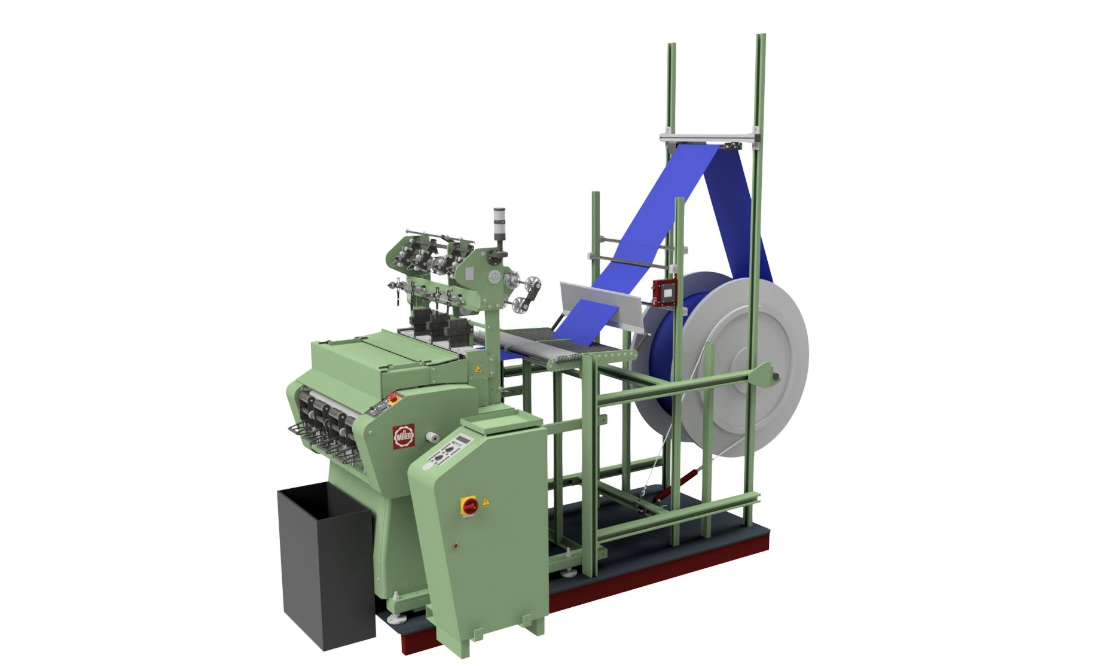

Crealet’s mission is to empower narrow weaving with a consistent high-quality level. The cost of electronic solutions depends on various factors, such as the complexity of the technology, the materials used as well as the market demand. Crealet makes continuous efforts to develop innovative and cost-effective solutions to meet customers’ needs. The new KAST ECR solution, presented for the first time at ITMA 2024, is an affordable warp feed system that fulfills the requirements of narrow weaving mills.

Crealet is the world leader in sophisticated warp feeding technology and tailored solutions. Controlled warp tension stands also for controlled fabric quality. The Swiss firm presents its latest developments for technical textile applications at Techtextil 2024 in Frankfurt, Germany.

The year 2023 was notably successful for Crealet, with a significant increase in sales compared to the previous year. This increase is the result of growing customer demand for optimisation and automation of the warp feeding process, also taking sustainability aspects into account. This trend reflects a major shift towards intelligent warp feeding technology also possible by converting an existing manual into an automated system. Such investments enable mills to significantly improve quality, efficiency and productivity.

KAST ECR for ribbon weaving mills

Crealet’s mission is to empower narrow weaving with a consistent high-quality level. The cost of electronic solutions depends on various factors, such as the complexity of the technology, the materials used as well as the market demand. Crealet makes continuous efforts to develop innovative and cost-effective solutions to meet customers’ needs. The new KAST ECR solution, presented for the first time at ITMA 2024, is an affordable warp feed system that fulfills the requirements of narrow weaving mills.

Crealet KAST ECR on a Jakob Müller narrow fabric loom

The KAST ECR warp let-off device keeps the warp tension automatically consistent and eliminates the need for manual adjustment. With the KAST ECR solution, warp tension is measured with load cells and the braking force is regulated by continuously changing the rope tension so that a uniform warp tension is achieved from the full to the empty package. By retrofitting the common rope brakes, as used to manually manage warp thread tension, with the ECR control unit, a system is created that automatically adjusts the warp tension during the weaving process. That’s crucial for the production of high-quality fabrics.

The KAST ECR control unit displays the set and actual values of the warp thread tension both numerically and graphically. Specifically developed for narrow weaving, this control meets highest demands and can be easily and quickly adapted to customer and product requirements. A significant future-oriented advantage of the KAST ECR solution is the reproducibility of the production data.

Production and cost optimisation

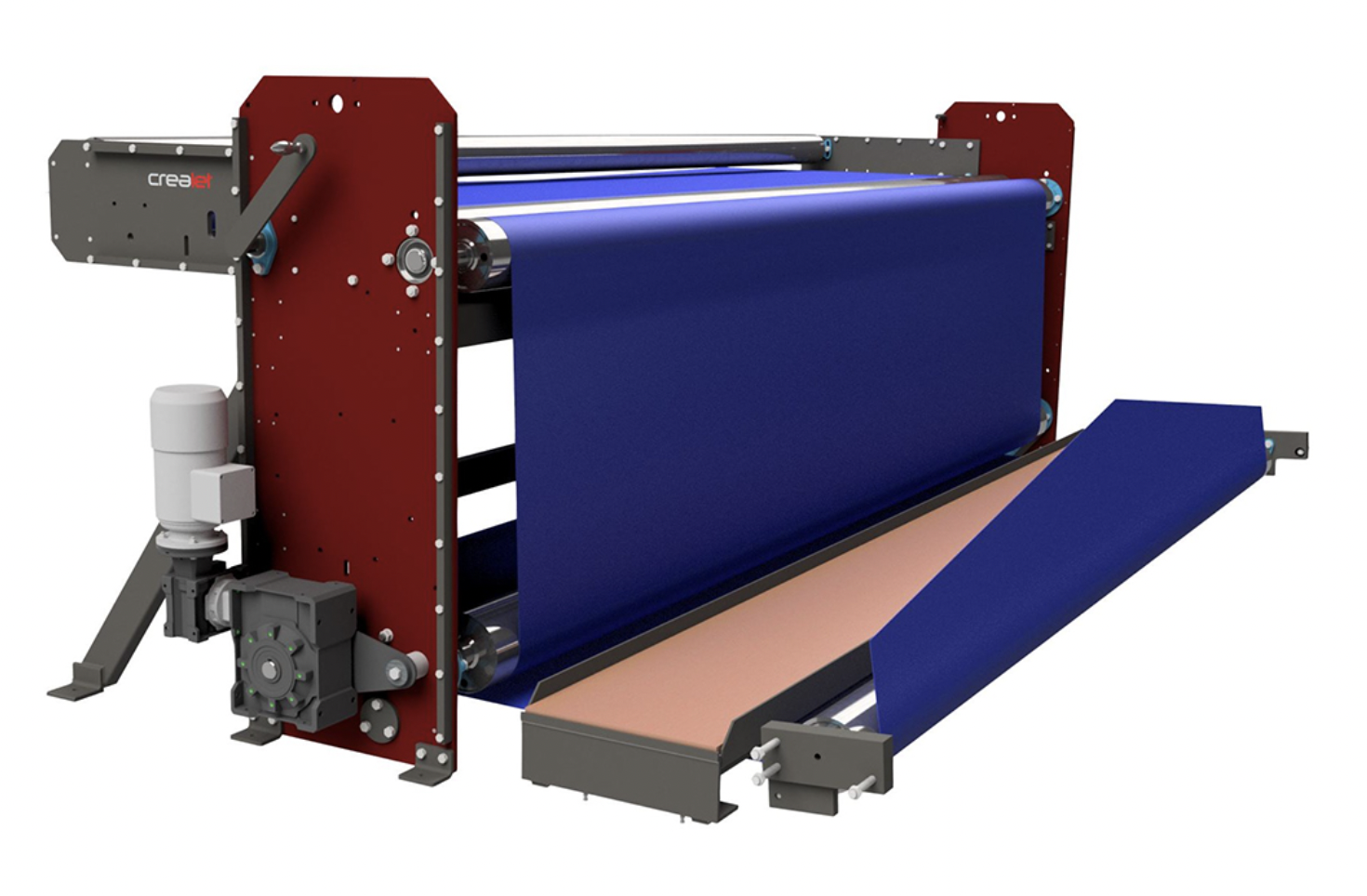

Crealet has its roots in traditional broadloom weaving and is still a leading supplier of electronic warp thread feeders for creels or warp beams for weaving and warp knitting machines. In the field of technical textiles, the Swiss company develops feeders for filter fabrics, geotextiles, aerospace textiles, and medical textiles. The production of these fabrics is often subject to more stringent requirements, with warp tension playing an important role and requiring the use of appropriate control devices. Crealet also offers solutions for the electronic feeding of thread groups to weaving machines for marking fabrics for further processing and preventing wavy selvedges.

The KAST ECR control unit displays the set and actual values of the warp thread tension both numerically and graphically. Specifically developed for narrow weaving, this control meets highest demands and can be easily and quickly adapted to customer and product requirements. A significant future-oriented advantage of the KAST ECR solution is the reproducibility of the production data.

Production and cost optimisation

Crealet has its roots in traditional broadloom weaving and is still a leading supplier of electronic warp thread feeders for creels or warp beams for weaving and warp knitting machines. In the field of technical textiles, the Swiss company develops feeders for filter fabrics, geotextiles, aerospace textiles, and medical textiles. The production of these fabrics is often subject to more stringent requirements, with warp tension playing an important role and requiring the use of appropriate control devices. Crealet also offers solutions for the electronic feeding of thread groups to weaving machines for marking fabrics for further processing and preventing wavy selvedges.

Crealet selvedge thread feeder LT3

Techtextil 2024 is for Crealet the ideal place to meet interested parties and explain in detail how to benefit from their devices and systems. Through cost reductions in production for example. Cost reductions can also be achieved in the area of warp thread feeding ranging from reducing set-up times and increasing machine uptime to minimising quality defects. Employees who can focus on their core tasks by reducing ancillary activities also play an important role. The solutions are very diverse and can be tailored individually to customers.

There’re many good reasons to meet the Crealet experts from April 23 to 26, 2024 at Techtextil Frankfurt, Germany. Crealet will be glad to welcome visitors and is proud to present its comprehensive range of warp yarn feeders for ribbon and wide weaving machines as well as warp knitting machines at the joint stand of the Swiss Textile Machinery Association in Hall 12.0, Stand B01.

There’re many good reasons to meet the Crealet experts from April 23 to 26, 2024 at Techtextil Frankfurt, Germany. Crealet will be glad to welcome visitors and is proud to present its comprehensive range of warp yarn feeders for ribbon and wide weaving machines as well as warp knitting machines at the joint stand of the Swiss Textile Machinery Association in Hall 12.0, Stand B01.